Empower Your Manufacturing Process With Cutting-Edge Computer Hardware For Manufacturers

Computer Hardware for Manufacturers

Introduction

Hello Readers,

2 Picture Gallery: Empower Your Manufacturing Process With Cutting-Edge Computer Hardware For Manufacturers

Welcome to our article on computer hardware for manufacturers. In today’s digital age, computer hardware plays a crucial role in the manufacturing industry. It enables manufacturers to streamline their operations, increase efficiency, and stay competitive in the market. In this article, we will provide you with a comprehensive overview of computer hardware for manufacturers, including its significance, types of hardware, advantages, and disadvantages. So, let’s dive in and explore the world of computer hardware for manufacturers.

Overview of Computer Hardware for Manufacturers

Image Source: 123rf.com

Computer hardware for manufacturers refers to the physical components and devices used in manufacturing processes that rely on computer systems. These hardware components are essential for automating tasks, controlling machinery, collecting and analyzing data, and managing various aspects of the manufacturing operations.

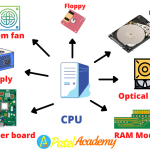

There are several types of computer hardware commonly used in the manufacturing industry, including:

Central Processing Units (CPUs) and servers

Industrial computers and embedded systems

Data storage devices

Input and output devices

Networking equipment

Sensors and actuators

Robotics systems

Each of these hardware components plays a specific role in the manufacturing process, contributing to improved productivity, quality control, and decision-making.

What is Computer Hardware for Manufacturers?

Image Source: thomasnet.com

Computer hardware for manufacturers encompasses all the physical equipment and devices used in the manufacturing industry to support and enhance various operations. It includes both the main hardware components, such as CPUs and servers, as well as peripheral devices like scanners, printers, and touchscreens.

Manufacturers rely on computer hardware to automate processes, monitor production lines, collect and analyze data, and control machinery. This helps in optimizing production, reducing costs, improving quality, and ensuring compliance with industry standards.

Who Uses Computer Hardware for Manufacturers?

Computer hardware for manufacturers is utilized by various stakeholders involved in the manufacturing industry, including:

Large-scale manufacturing companies

Small and medium-sized enterprises (SMEs)

Original Equipment Manufacturers (OEMs)

Industrial automation specialists

System integrators

Manufacturing engineers and technicians

These entities recognize the value of computer hardware in improving efficiency, streamlining processes, and gaining a competitive edge in the market.

When is Computer Hardware for Manufacturers Used?

Computer hardware for manufacturers is used throughout the manufacturing process, from product design and development to production, quality control, and distribution. It is employed in various stages, such as:

Computer-aided design (CAD) and simulation

Prototyping and testing

Production planning and scheduling

Inventory management

Quality control and inspection

Data collection and analysis

Supply chain management

By integrating computer hardware into these stages, manufacturers can streamline their operations, reduce manual tasks, and ensure accurate and efficient production.

Where is Computer Hardware for Manufacturers Implemented?

Computer hardware for manufacturers is implemented in various manufacturing environments, including:

Factory floors

Assembly lines

Production facilities

Research and development labs

Quality control centers

Warehouse and logistics operations

These environments require robust and reliable computer hardware to withstand the challenging conditions, such as temperature variations, dust, and vibrations, while ensuring uninterrupted operations.

Why is Computer Hardware Important for Manufacturers?

Computer hardware is of utmost importance for manufacturers due to several reasons:

Automation and Efficiency: Computer hardware enables manufacturers to automate processes, reducing the need for manual labor and increasing efficiency.

Data Management: With the help of computer hardware, manufacturers can collect, store, and analyze data to make informed decisions, identify areas for improvement, and optimize production.

Quality Control: Computer hardware plays a vital role in ensuring quality control by monitoring and controlling various parameters during the manufacturing process.

Real-time Monitoring: By utilizing computer hardware, manufacturers can monitor production lines, machinery, and equipment in real-time, enabling timely interventions and minimizing downtime.

Communication and Collaboration: Computer hardware facilitates seamless communication and collaboration between different teams and departments involved in the manufacturing process.

Competitive Advantage: By leveraging advanced computer hardware, manufacturers can gain a competitive edge by staying updated with the latest technologies and trends in the industry.

Cost Reduction: Computer hardware helps in optimizing production, reducing waste, and minimizing operational costs, resulting in improved profitability.

How Does Computer Hardware for Manufacturers Work?

Computer hardware for manufacturers works by integrating various components and devices to create a robust and interconnected system. The hardware components collaborate to perform specific functions, such as:

Processing and analyzing data

Controlling machinery and equipment

Communicating and exchanging information

Storing and retrieving data

Monitoring and tracking production parameters

Executing commands and instructions

These operations are carried out by a combination of software and hardware, ensuring seamless and efficient manufacturing processes.

Advantages and Disadvantages of Computer Hardware for Manufacturers

Like any technology, computer hardware for manufacturers has its own set of advantages and disadvantages. Let’s explore them in detail:

Advantages:

Increased Efficiency: Computer hardware automates tasks and processes, resulting in improved productivity and efficiency.

Quality Control: By monitoring and controlling various parameters, computer hardware helps in ensuring consistent quality throughout the manufacturing process.

Real-time Data Analysis: With computer hardware, manufacturers can analyze real-time data to identify issues, make informed decisions, and optimize production.

Streamlined Operations: Computer hardware streamlines production processes, reduces manual tasks, and minimizes errors and delays.

Improved Collaboration: Computer hardware enables seamless communication and collaboration between different teams and departments, enhancing overall productivity.

Disadvantages:

Initial Investment: Implementing computer hardware requires a significant upfront investment, including the cost of hardware, software, and training.

Technical Challenges: Manufacturers may face technical challenges, such as compatibility issues, software updates, and hardware failures, which can disrupt operations.

Security Risks: The increased reliance on computer hardware makes manufacturers more susceptible to cybersecurity threats and data breaches.

Dependency on Technology: In case of hardware or software failures, manufacturers may experience downtime and delays in production.

Skill Requirements: Utilizing computer hardware requires a skilled workforce who can operate, maintain, and troubleshoot the hardware components effectively.

Frequently Asked Questions (FAQ)

1. Can computer hardware improve manufacturing efficiency?

Yes, computer hardware plays a crucial role in improving manufacturing efficiency by automating tasks, optimizing production processes, and enabling real-time data analysis.

2. What are the key components of computer hardware for manufacturers?

The key components of computer hardware for manufacturers include CPUs, servers, industrial computers, data storage devices, input and output devices, networking equipment, sensors, actuators, and robotics systems.

3. Is computer hardware necessary for small-scale manufacturing businesses?

Yes, computer hardware is equally important for small-scale manufacturing businesses as it helps in streamlining operations, improving productivity, and staying competitive in the market.

4. Are there any risks associated with computer hardware in manufacturing?

Yes, there are risks associated with computer hardware in manufacturing, such as potential cybersecurity threats, technical challenges, and dependency on technology.

5. How can manufacturers ensure the security of their computer hardware?

Manufacturers can ensure the security of their computer hardware by adopting robust cybersecurity measures, regularly updating software and firmware, implementing access controls, and providing employee training on cybersecurity best practices.

Conclusion

In conclusion, computer hardware for manufacturers is a critical component of modern manufacturing operations. It empowers manufacturers to automate processes, optimize production, ensure quality control, and stay competitive in the market. While computer hardware offers numerous advantages, it also comes with certain challenges and risks. However, with proper planning, implementation, and cybersecurity measures, manufacturers can leverage computer hardware to enhance their operations and achieve sustainable growth in the ever-evolving manufacturing landscape.

Final Remarks

Dear Readers,

Computer hardware for manufacturers has revolutionized the manufacturing industry, offering unprecedented opportunities for growth and efficiency. However, it is essential to remember that technology is constantly evolving, and staying updated with the latest trends and advancements is crucial for manufacturers to thrive in the competitive market. We hope this article has provided valuable insights into computer hardware for manufacturers and its significance in the manufacturing landscape. If you have any further questions or need assistance in implementing computer hardware solutions for your manufacturing business, feel free to reach out to our expert team. Happy manufacturing!

This post topic: Computer Hardware